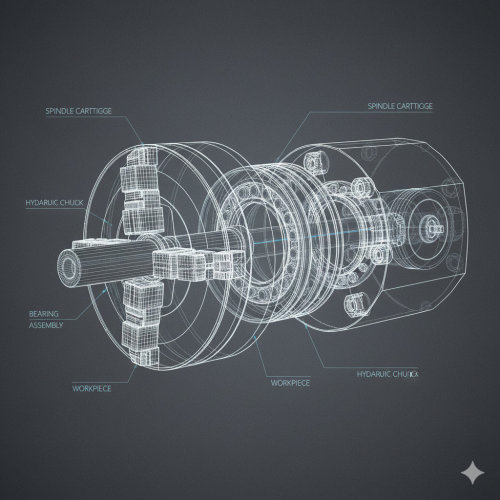

Stable Structure Design of CNC Lathe Spindles — How FEPO Precision Technology Supports Advanced Manufacturing

With over 30 years of engineering experience, FEPO specializes in designing and manufacturing high-precision CNC lathe spindles, hydraulic tailstocks, manual tailstocks, and customized motion modules.